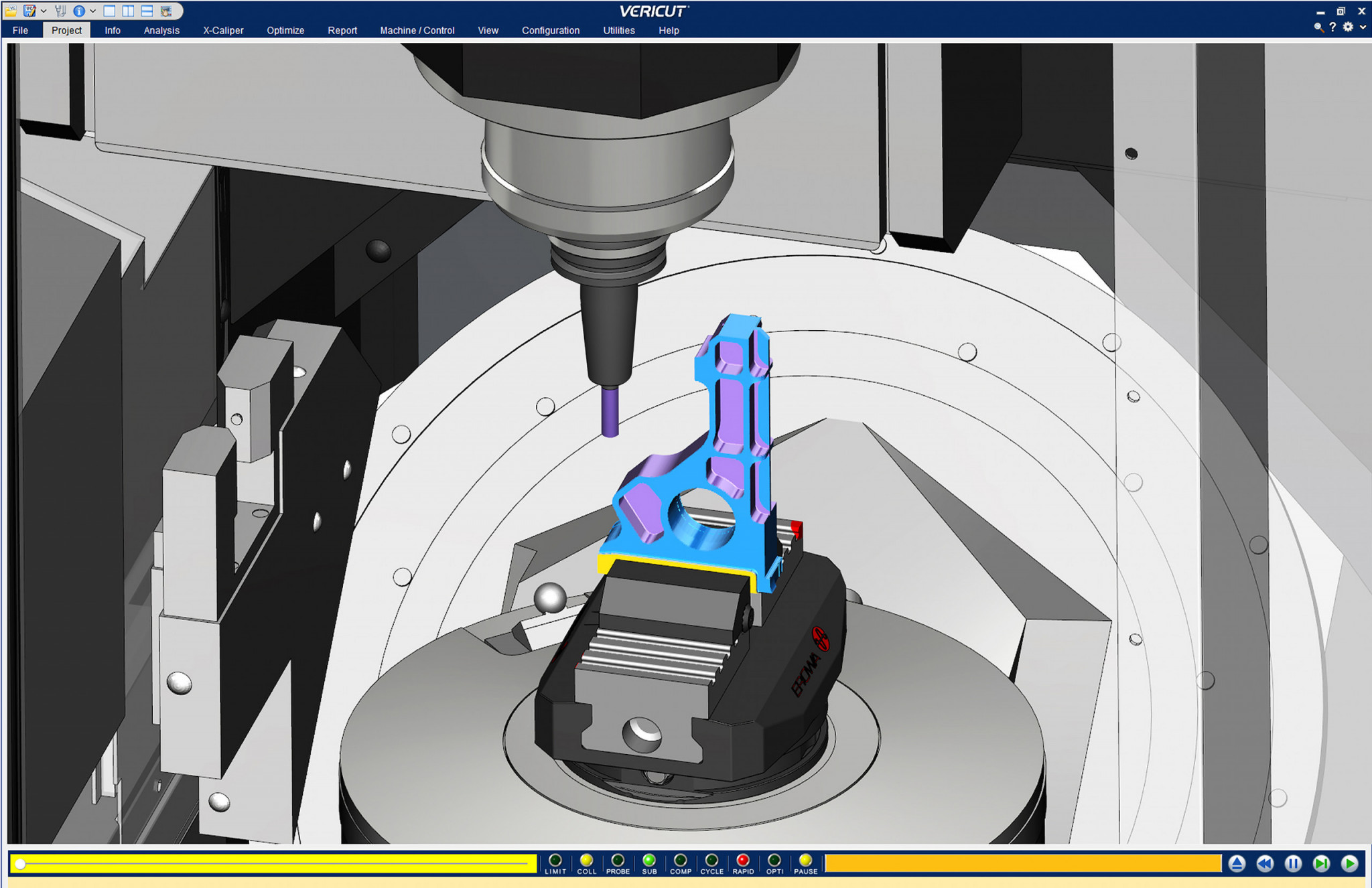

CGTech VERICUT Machine Simulation

VERICUT simulates all types of CNC machine tools, including those from leading manufacturers such as Mazak, Makino, DMG / Mori Seiki, Okuma, etc. VERICUT runs standalone, but can also be integrated with all leading CAM systems.

About CGTech

Since 1988 CGTech’s product, VERICUT software, has become the industry standard for simulating CNC machining in order to detect errors, potential collisions, or areas of inefficiency. The software also optimizes NC programs in order to both save time and produce higher quality surface finish.

Benefits and Features

Verification

VERICUT verification makes detecting program mistakes and verifying part accuracy easy. VERICUT’s error-detection is extremely accurate and all errors are recorded in a results file. VERICUT accurately emulates CNC control logic and can account for different types of machines, programs, parts, and functions. No special programming language is required to simulate most CNC controls.

Verification detects errors such as:

- Incorrect or misread blueprints

- Inaccurate programming

- Incorrect tool path motions

- Rapid motion contact

- Collisions with fixtures and clamps

- Tool shank and holder collisions

- CAD/CAM and post-processor bugs

Machine Simulation

VERICUT enables you to perform realistic 3D simulation of entire CNC machines, just like they behave in the shop. CNC Machine Simulation detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, work pieces, cutting tools, and other user-defined objects. You can set up ‘near-miss zones” around the components to check for close calls, and even detect over-travel errors.

With VERICUT CNC Simulation you can:

- Simulate traditional and multi-axis (4, 5 or more) CNC machines

- Help to avoid CNC machine collisions and safety distance problems

- Reduce the time it takes to implement new CNC machines

- Provide clear instructions for the operator on new NC programs

- Improve process efficiency

- Improve operational safety

- Enhance presentations and documentation

- Train programmers and operators without using production time or risking collisions

Force Optimization

Cut parts faster, improve surface finish, & reduce tool wear without altering the path trajectory. VERICUT’s Force optimization module automatically modifies feed rates based on the cutting conditions to make your programs more efficient, while also extending tool life and improving surface finish.

Benefits of Force:

- Significant cycle time savings

- Charted cutting condition information for NC program analysis

- FAST analysis and iteration for testing various cutting scenarios

- Maximized and more consistent chip thickness throughout the machining process

- Cut-by-cut analysis of the interaction between the cutting tool edge and the material

- Improved cutting tool performance—utilize cutting tool technologies to their full potential

- Prevention of undesirable cutting conditions like excessive force, HP/Torque, and tool deflection

CNC Machine Connectivity

Establish a Live Connection to CNC Machines on the Shop Floor with VERICUT’s CNC Machine Connectivity modules.

CNC Precheck ensures that key aspects of the machine setup match what was verified in VERICUT. Differences identified can then be investigated and resolved before running the machine and risking problems resulting from those differences.

CNC Precheck allows you to:

- Check that parameters from your physical machine and VERICUT’s virtual machine match

- Verify that job setup information on the machine (NC programs, subprograms, work offsets, etc.) matches with corresponding VERICUT setups

- Verify cutting tools and their length offsets match with VERICUT

CNC Machine monitoring allows you to live stream and monitor what your machines in the shop are doing, in real time, within VERICUT.

CNC Machine Monitoring enables users to observe how the machine is functioning live as it is happening on the shop floor:

- Observe what machines in the shop are doing

- See which NC program or subroutine is running

- Observe active tool and work offsets

- Monitor machine axis positions/motion and spindle activity

- See if spindle or feedrate overrides are applied

- See if machine is (or isn’t) running or in Emergency stop

Customers already benefit from the ICAM & CGTech alliance

Thousands of companies already rely on ICAM and CGTech every day. Now the two companies have teamed up to create a streamlined process for our customers.

Machine tool manufacturers and distributors can also benefit

- Customer satisfaction is guaranteed by offering Best-in-Class software solutions with their Best-in-Class CNC machines:

-

- A great post-processor provides unparalleled control of your machine’s most advanced features. An inadequate post-processor limits machine tool capability and can even delay payment on the machine!

-

- Customers can start programming even prior to machine delivery

- Peace of mind knowing customers have crash prevention

Integrates ahead with ICAM and VERICUT

““ICAM offers the option of creating a generic post-processor using a questionnaire. […] When we order a new machine, I use the VERICUT simulation to test my post-processor in order to eliminate the worst errors even before the machine is physically commissioned.”

– CAD/CAM manager, Susanne Klamma and a CGTech and ICAM user.