Get Powerful Post-Processors for any CAD/CAM System

Industry leaders in aerospace, automotive and other highly-competitive manufacturing markets rely on ICAM to develop dedicated CNC post-processors tailored to their particular manufacturing environment.

Mastercam Post-Processor in Progress

Mastercam Post-Processor Full

Mastercam Post-Processor Virtual Machine

3DEXPERIENCE Post-Processor in Progress

3DEXPERIENCE Post-Processor Full

NX CAM Post-Processor in Progress

NX CAM Post-Processor Full

NX CAM Post-Processor Virtual Machine

CATIA V5 Post-Processor in Progress

CATIA V5 Post-Processor Full

CATIA V5 Post-Processor Virtual Machine

Creo Post-Processor in Progress

Creo Post-Processor Full

CNC post-processors custom-built for your unique machine setup and CAD/CAM System

At ICAM we’ve been building world-class custom CNC post-processors for over 50 years. Thanks to our in-depth machining and industry knowledge, partnerships with major CAM systems and exclusive CAM-POST development platform , we can build exceptional posts for all major machine tools and CNC controller brands, including all classes of CNC equipment featuring any combination of rotary heads and/or rotary tables.

Mills, Lathes, Horizontal/ Vertical Machining Centers, Merging Lathes, Multi-Tasking Mill/ Turns, Punch Presses, Wire EDMs, Water Jet Cutting Machines, Laser Cutting Machines, Plasma & Flame Cutters, Hybrid and Special CNCs.

Go From Mastercam3DEXPERIENCESIEMENS NXCAD/CAM File to Verified & Optimized G-Code in One Process

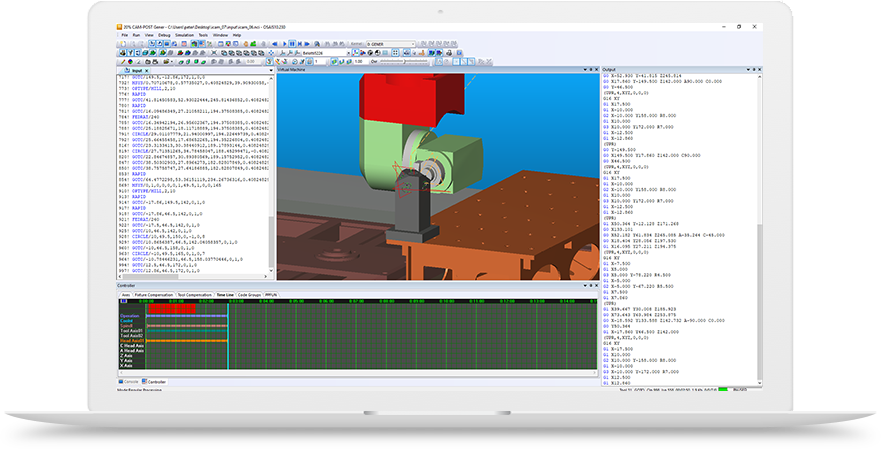

While the majority of post-processors available today simply generate G-Code from your CAD/CAM file, leaving you to verify, test and optimize the code yourself, ICAM’s CNC post-processors provide a one-step solution for machine simulation, tool-path optimization & post-processing resulting in better code in less time.

We call this innovative technology Adaptive Post-Processing™. By taking the trial and error out of the NC programming process it has helped manufacturers the world over save up to 35% in programming and machining time.

The G-Code you want,

where and when you want it.

With generic CNC post-processors, you’re often stuck manually modifying your G-Code to get it match up with your existing machining methodology and preferences. But with our custom-developed CNC posts, we build your preferences and practices into the post itself, allowing you to focus on designing your best tool-paths, while we handle the nitty-gritty.

Transformation

Supports translation, rotation, scale, mirror and additive transformations.

Canned Cycles

Run your controller’s predefined cycles for drilling, milling, turning and probing.

Compensation

Compensate for deviations with 3D volumetric, spindle-pitch, tool radius, and more.

Custom Macros

Fine-tune your NC output even further with powerful, custom-developed macros.

Built-in machine simulation sees and corrects errors before they happen

Rotary Pre-Winding

Extend the travel of your rotary axis by automatically winding the axis backwards before the cut, avoiding unnecessary retracts, turn-arounds and approaches.

Head-Dancing Avoidance

Automatically eliminate head and table wobbling when moving along low-angle, near- singular compound curves

Dwell mark Elimination

Take advantage of several CAM-POST features that are designed to eliminate dwell marks caused by momentary pauses in tool motions.

Industry leaders who use ICAM’s Post-processors